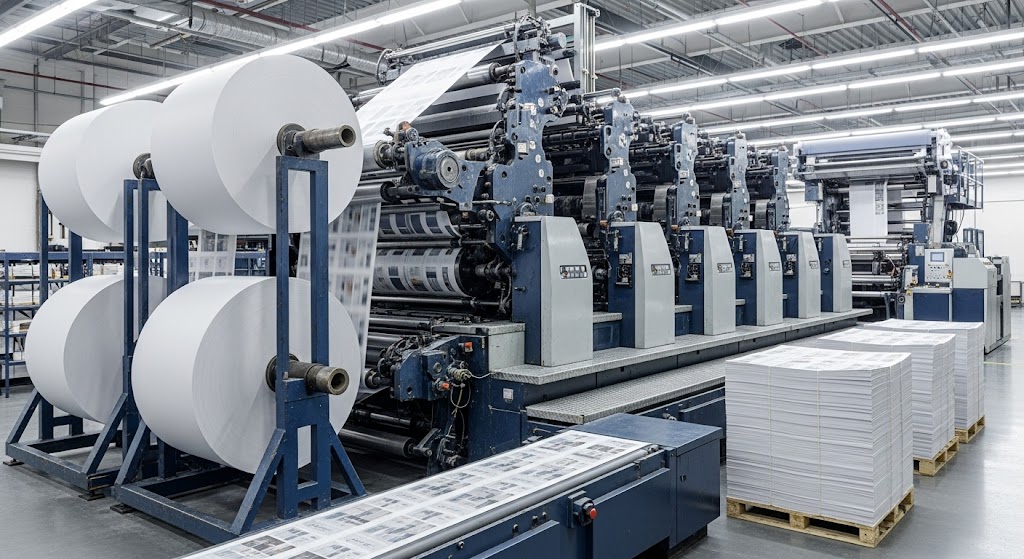

Coldset printing is a specialized form of offset lithography in which ink dries naturally by being absorbed into the paper rather than through the application of heat. This method excels on uncoated stocks such as newsprint and other lightweight webs, delivering high-speed production without cumbersome drying ovens. Many Printing Services in Monroe leverage this technique to offer clients rapid turnaround on mass mailers, newspapers, and catalogs. Because the inks set through evaporation and absorption, coldset presses can run continuously with minimal downtime, making them ideal for projects that demand both volume and budget efficiency.

The Science Behind Ink Absorption

At its core, coldset offset printing relies on the interaction between fountain solution and ink on a metal plate. The non-image areas attract water from a dampening system, preventing ink from adhering, while the image zones accept oil-based offset inks. As sheets travel through the press, the paper’s porosity draws the wet ink off the press blanket and into the fibers. This process eliminates the need for dryers, reduces energy consumption, and streamlines pressroom workflows, ultimately boosting throughput.

How Does Coldset Offset Printing Compare to Other Methods?

Offset printing, digital printing, and coldset web press solutions each serve unique roles in commercial production. Offset lithography broadly involves transferring ink from a plate to a rubber blanket before applying it to a substrate, while digital presses bypass plates entirely but carry higher per-unit costs on large runs. Heatset offset uses ovens to quickly cure inks on coated stocks, achieving glossy finishes but at greater energy and equipment expense. In contrast, coldset offset printing remains the champion for high-volume newspaper printing thanks to its lean setup and economical paper requirements.

| Feature | Coldset Offset | Heatset Offset | Digital Printing |

| Drying Method | Ink absorption into uncoated web | Heated ovens evaporate solvents | Inkjet or toner fusion |

| Suitable Substrates | Newsprint, lightweight rolls | Coated papers, magazines, flyers | Coated and uncoated up to specialty |

| Typical Use | Newspapers, directories | High-end catalogs, art books | Personalized prints, short runs |

| Cost Efficiency | Best for 10,000+ copies | Best for 5,000–20,000 glossy runs | Ideal under 1,000 copies |

A clear advantage of coldset lies in its lower cost per piece and continuous production capability, making it the preferred choice when quantity outweighs immediate print sheen.

Many mid-sized enterprises and regional publications turn to Commercial Printing Services Monroe when they need a trusted partner to handle large-scale newspaper and flyer projects on tight deadlines. The seamless integration of automated plate changers and automated ink controls in modern web presses ensures consistency across millions of impressions per month.

Why Printing Services in Monroe Choose Coldset Offset Printing

Printing Services in Monroe capitalize on coldset offset printing to deliver unmatched value for high-volume projects. Local publishers, direct mail marketers, and regional retailers benefit from the process’s rapid throughput and economical running costs. By selecting coldset, these businesses can allocate more budget toward design, distribution, and audience engagement rather than expensive drying equipment or premium coated stocks. You can also Save on Postage with new postal promotions, further maximizing your budget.

Cost Savings and Efficiency in High-Volume Newspaper Printing

When production goals exceed tens of thousands of copies, coldset offset printing consistently outperforms alternative methods in cost per unit. The absence of ovens and the use of uncoated newsprint reduce both capital investments and variable costs. In a typical scenario, a run of 50,000 newspaper editions on a coldset web press can be executed in a single shift, whereas the same run on a sheetfed or digital press might require multiple setups and additional passes.

| Volume of Copies | Coldset Cost per Unit | Digital Cost per Unit |

| 5,000 | $0.035 | $0.085 |

| 20,000 | $0.025 | $0.065 |

| 50,000 | $0.018 | $0.055 |

These figures underscore why high-volume newspaper printing remains synonymous with coldset offset technology. Monroe’s printing specialists tailor each job to balance speed, quality, and price, ensuring brand messages reach readers affordably.

Which Industries Benefit Most from Coldset Web Press Solutions?

Newspapers and directories have long formed the backbone of coldset applications, but the technology now spans broader niches. Retail chains commission weekly ad circulars, nonprofit organizations distribute newsletters, and academic institutions publish student papers—all in massive quantities. The pressroom consumables ecosystem, including fountain concentrates, rollers, and blankets, further refines output quality while keeping operations cost-effective.

Beyond publishing, coldset web press solutions excel for company manuals, large-format coupons, and product catalogs. Trade associations frequently ink thousands of copies of industry reports, relying on the rapid turnaround offered by web-fed coldset presses.

Midwest co-ops and regional distributors looking to streamline their bulk mail campaigns often tap into Offset Printing Services Monroe resources. The deep bench of in-house finishing options—folding, binding, inserting—enables a single provider to manage both press and post-press workflows for complex, variable-data jobs.

Applications Beyond Newspapers

In addition to periodicals, coldset offset printing addresses marketing collateral that demands volume above all else. Event programs, direct mail pieces, and introductory brochures for new product lines roll off presses in nearly the same time it takes to warm up a heatset line. Coupled with digital personalization units, hybrid print operations now blend coldset’s economy with tailored messaging, engaging customers at scale.

What Are the Key Components of a Coldset Web Press?

A coldset web press integrates multiple towers, each housing a fountain solution circuit, ink rollers, and a plate cylinder. The plate, typically made from aluminum, carries the image to the rubber blanket, which in turn transfers the ink to the continuous paper web. Core press sections include:

– Infeed and web tension controls to maintain consistent paper flow

– Plate changer systems for quick job turnover

– Automated impression cylinders for pressure consistency

– Folder and cutoff units that transform continuous prints into usable products

Advanced presses such as the Goss Universal series can exceed 60,000 impressions per hour, generating millions of pages monthly.

The Role of Fountain Solutions and Ink

Fountain solutions maintain the delicate balance between water and ink coverage on the plate. Coldset formulas range from acid to neutral pH, with options certified by FOGRA for minimal scumming and toning. Ink chemistries prioritize transfer performance without piling, ensuring sharp reproduction of CMYK process colors even at high speeds. Precision controls for ink feed and dampening water guarantee that each print emerges with consistent tone and registration.

How to Select the Right Coldset Offset Printer

Choosing an optimal coldset partner involves assessing equipment capabilities, turnaround schedules, and quality assurances. Prospective clients should inquire about minimum run lengths, plate changeover times, and the press’s maximum web width. A printer with multiple towers and in-line finishing modules offers flexibility for tabloid, broadsheet, and booklet formats, accommodating diverse project needs.

Equally important is the provider’s prepress workflow. Computer-to-plate systems expedite job setups, while remote proofing portals grant clients direct visibility into proof approval processes. Established hot folders and secure file transfer protocols reduce errors, leading to smoother production runs.

Questions to Ask Your Printing Partner

When vetting a coldset printer, ask about pressroom certifications such as Six Sigma or ISO 9001, which signal rigorous quality checks. Inquire whether they offer integrated digital print options for variable data and short runs. Verify their sustainability initiatives—use of recycled newsprint, vegetable-based inks, and water-saving dampening technologies speak to environmental responsibility.

What Environmental Advantages Does Coldset Offset Printing Offer?

Because coldset presses do not require heatset ovens, they consume significantly less energy per ton of paper processed. This reduction in power demand, combined with the ability to run uncoated and recycled papers, leads to smaller carbon footprints. Additionally, many suppliers now provide biodegradable fountain solutions and soy- or vegetable-based inks, further enhancing green credentials.

Pressroom effluents are minimal, as there are no dryer exhaust streams to treat. Waste management focuses chiefly on paper trim and plate disposal, both of which can be recycled efficiently. Such eco-friendly practices align with corporate sustainability goals, helping brands demonstrate social responsibility to consumers and stakeholders alike.

contact us to learn how your next publication can be produced more sustainably through coldset offset printing.

Sustainable Practices and Materials

Modern coldset operations often partner with FSC- and SFI-certified paper mills to guarantee ethically sourced substrates. They adopt closed-loop water filtration for fountain solution reuse and optimize ink formulations to minimize volatile organic compounds (VOCs). By integrating renewable energy sources and comprehensive recycling programs, leading printers set a new standard for eco-conscious mass production.

How Do Commercial Printers in Monroe Deliver Cost-Effective Offset Printing?

Regional printers in Monroe combine decades of offset expertise with cutting-edge automation to drive down costs. From precise plate calibration to real-time ink density scanners, every stage is monitored for efficiency. They leverage economies of scale, negotiating favorable rates on raw newsprint rolls and consumables, passing savings directly to clients.

To learn more about how modern technology is revolutionizing the industry, check out this resource on Unlocking Print Efficiency.

In-house finishing facilities eliminate third-party handling, slashing lead times and shipping overhead. Full-service shops handle design tweaks, proofing, printing, folding, binding, and mailing under one roof, ensuring seamless coordination and cost containment.

Power users in the area routinely rely on Printing Services in Monroe to orchestrate complex, variable-data mailers that merge personalized messaging with the affordability of coldset. The outcome: high-volume runs that don’t compromise on clarity, color fidelity, or delivery schedules.

Maximizing Value with Integrated Services

By bundling prepress, press, post-press, and logistics, comprehensive providers deliver turnkey solutions at predictable price points. This integrated approach reduces administrative overhead and creates a single accountability channel, streamlining communication and project management for both regular and one-off campaigns.

What Future Trends Will Shape Coldset Offset Printing?

As the industry evolves, coldset offset printing is poised to intertwine with digital and data-driven channels. Smart presses armed with IoT sensors will optimize ink-water balances in real time, reducing makereadies and waste. Hybrid models that fuse web-fed coldset and digital inkjet units will allow personalization directly on continuous rolls, bringing variable data to high-volume runs.

Augmented reality packaging and interactive ink coatings may soon emerge on newsprint-style substrates, bridging the gap between tactile print and digital engagement. Artificial intelligence-powered color management will further enhance consistency across extended runs and multi-site production networks.

The Rise of Hybrid and Digital-Offset Solutions

In this hybrid paradigm, businesses can combine the low per-unit cost of coldset printing with on-demand QR integration, enabling trackable URLs, dynamic content updates, and personalized call-to-actions. As a result, marketing materials will become living documents, maintaining relevance long after the press stops.

Conclusion

Coldset offset printing stands as a time-tested, cost-effective cornerstone for high-volume publishing, from newspapers and magazines to marketing catalogs and direct mail campaigns. Its natural ink absorption process, energy-efficient operation, and compatibility with uncoated stocks ensure that enterprises can reach audiences affordably and at scale. As the market shifts toward more sustainable and personalized experiences, coldset web press solutions will continue to evolve, integrating smarter controls and digital enhancements. For organizations seeking reliable, economical, and scalable Printing Services in Monroe, Walton Press delivers expertise, advanced equipment, and full-service capabilities to transform your next large-run project into a resounding success.

Frequently Asked Questions

What makes coldset offset printing more affordable than other methods?

Coldset offset printing avoids the capital and operating expenses of heatset dryers and relies on uncoated papers, which are less expensive. The cost per unit decreases dramatically with larger volumes, making it ideal for newspaper and directory runs.

Can coldset printing produce full-color images comparable to heatset or digital?

Yes, modern coldset inks use CMYK process colors and can mix dexterous spot colors to achieve vibrant results. While the finish is more matte than glossy heatset prints, color reproduction remains consistent across large runs.

Is coldset offset printing suitable for short-run projects?

Typically, coldset excels at quantities over 5,000 copies due to plate and setup requirements. For runs under 1,000, digital printing often provides faster turnaround and lower total cost.

How does a coldset press handle variable-data printing?

Coldset presses traditionally output identical copies, but hybrid workflows that pair digital inkjet modules downstream enable personalized elements on each sheet before folding and binding.

What environmental certifications should I look for in a coldset print provider?

Seek printers using FSC-certified or SFI-certified paper, vegetable-based inks, and fountain solutions with low or zero VOCs. ISO 14001 and other eco-management standards are good indicators of environmental commitment.