Choosing the right commercial printing partner is crucial for businesses looking to produce high-quality printed materials. The selection process can significantly impact the quality of your marketing materials, product packaging, and overall brand image. This guide will help you understand the essential factors to consider when selecting a commercial printer, ensuring you make an informed decision that aligns with your business needs. We will explore key evaluation criteria, best practices for printer assessment, and common pitfalls to avoid during the selection process. By the end of this article, you will be equipped with the knowledge to choose a printing partner that meets your specific requirements.

What Are the Essential Factors for Selecting a Commercial Printer?

When selecting a commercial printer, several key factors should guide your decision-making process. These factors include the quality of printing, the capabilities of the printer, and the reputation and reliability of the printing service provider. Understanding these elements will help you identify a partner that can deliver the results you need.

Beyond technical capabilities, the character and commitment of a printing partner are also vital for a successful collaboration.

Key Qualities for Commercial Printing Partners

six expert participants in the US commercial printing industry with broad-based business partners, they should seek qualities that build on character and integrity, commitment from top

Factors for Successful Strategic Alliances Among Midsize Commercial Printing Companies, 2007

How to Evaluate Printing Quality and Capabilities

Evaluating printing quality and capabilities involves assessing various aspects of the printing process. Key metrics to consider include:

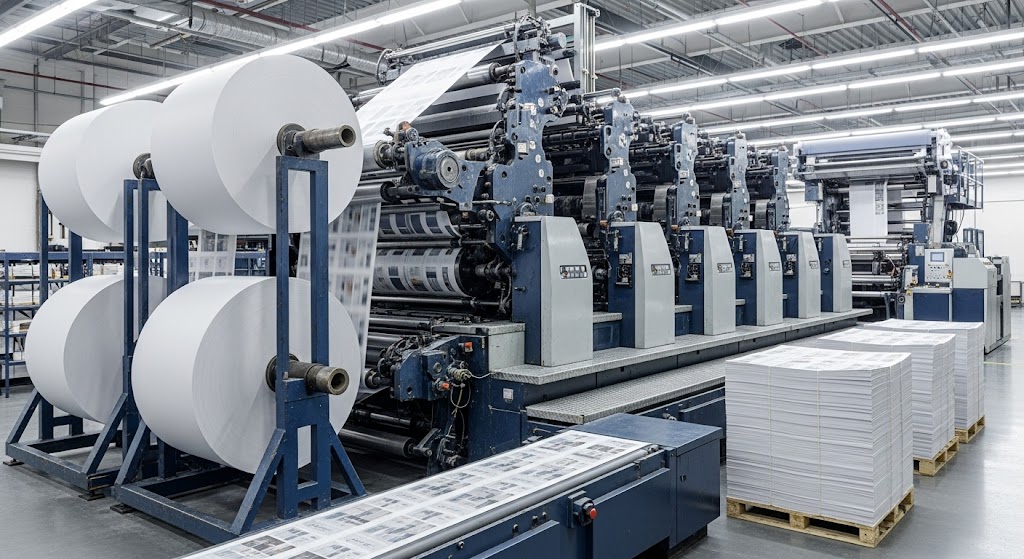

- Types of Printing Technologies: Different printers utilize various technologies, such as digital printing, offset printing, and large format printing. Each technology has its strengths and is suited for specific applications.

- Sample Evaluations: Requesting samples of previous work can provide insight into the printer’s quality. Look for consistency in color, clarity, and overall finish.

- Customer Feedback: Reviews and testimonials from previous clients can offer valuable information about the printer’s reliability and service quality.

When considering different printing technologies, it’s important to be aware of common quality issues and the need for robust quality assurance procedures.

Digital & Offset Print Quality Assurance

Using an Internet-based industry survey, the differences and similarities of offset and digital print demerits within the print industry are examined. Running parallel to this examination is a look at the extent to which demerit-based quality assurance procedures exist within the printing industry. The survey findings indicate that offset and digital printing processes share common color-related print demerits.

A survey of digital and offset print quality issues, 2007

By focusing on these evaluation methods, you can ensure that the printer you choose meets your quality standards.

Furthermore, a deeper technical assessment of print quality often involves complex image metrics, which require careful application.

Evaluating Print Quality with Image Metrics

quality attributes as suitable for image quality evaluation. The process of applying image quality metrics to printed images is not straightforward, because image quality metrics require a

Image quality metrics for the evaluation of print quality, M Pedersen, 2011

How to Assess Printing Service Providers Effectively?

Assessing potential printing service providers requires a structured approach. This involves asking the right questions and comparing their offerings to find the best fit for your needs.

What Questions Should You Ask Potential Print Partners?

When evaluating potential print partners, consider asking the following questions:

- What are your printing capabilities? Understanding the range of services offered can help you determine if they can meet your specific needs.

- What is your pricing structure? Inquire about pricing models and any additional costs that may arise during the printing process.

- What are your turnaround times? Knowing how quickly a printer can deliver your order is crucial for meeting deadlines.

These questions will help you gauge the printer’s suitability for your project.

How to Compare Pricing and Turnaround Times

Comparing pricing and turnaround times is essential for making an informed decision. Consider the following factors:

- Factors Affecting Pricing: Understand what influences the cost of printing, such as materials, complexity of the project, and volume.

- Importance of Turnaround Times: Timeliness is critical in the printing industry. Ensure that the printer can meet your deadlines without compromising quality.

- How to Negotiate: Don’t hesitate to negotiate pricing and terms. Many printers are willing to work with you to find a mutually beneficial agreement.

By carefully comparing these aspects, you can select a printing partner that aligns with your budget and timeline.

What Are the Best Practices for Printer Evaluation?

To ensure a thorough evaluation of potential printers, follow these best practices. These practices will help you make a well-informed decision.

How to Verify Certifications and Industry Experience

Verifying certifications and industry experience is vital in selecting a reliable printing partner. Consider the following:

- Types of Certifications: Look for printers with industry-recognized certifications, such as ISO 9001, which indicates a commitment to quality management.

- Industry Standards: Ensure that the printer adheres to industry standards for quality and safety.

- Experience Metrics: Assess the printer’s experience in your specific industry to ensure they understand your unique requirements.

These verification steps will help you identify a trustworthy printing partner.

Why Is Customer Service Important in Choosing a Print Partner?

Customer service plays a crucial role in the printing process. A printer with excellent customer service can make your experience smoother and more efficient. Consider these factors:

- Impact on Project Success: Good communication and support can significantly affect the outcome of your project.

- Communication Importance: Ensure that the printer is responsive and willing to address your concerns throughout the process.

- Support During the Process: A reliable printer should provide assistance from the initial consultation to the final delivery.

Prioritizing customer service will enhance your overall experience with the printing partner.

How to Choose a Print Partner That Aligns with Your Business Needs?

Choosing a print partner that aligns with your business needs involves understanding your specific requirements and evaluating how potential printers can meet them.

What Printing Technologies and Services Should You Consider?

When selecting a printing partner, consider the following technologies and services:

- Types of Printing Technologies: Evaluate the technologies offered, such as digital, offset, and large format printing, to determine which best suits your needs.

- Service Offerings: Look for additional services, such as bindery and mailing services, that can streamline your project.

- Customization Options: Ensure that the printer can accommodate any specific customization requests you may have.

By considering these factors, you can select a printer that meets your unique business needs.

How to Ensure Scalability and Flexibility in Your Print Partner

Scalability and flexibility are essential for businesses that anticipate growth or changing needs. Consider the following:

- Scalability Considerations: Choose a printer that can handle increased volumes as your business grows.

- Flexibility in Service Delivery: Ensure that the printer can adapt to your changing requirements, whether it’s adjusting timelines or accommodating new projects.

- Long-term Partnership Benefits: A printer that can grow with your business will provide long-term value and support.

By prioritizing scalability and flexibility, you can establish a productive partnership with your print provider.

What Are Common Mistakes to Avoid When Selecting a Commercial Printer?

Avoiding common pitfalls during the printer selection process can save you time and resources. Here are some mistakes to watch out for:

How to Avoid Hidden Costs and Quality Issues

Hidden costs and quality issues can arise if you’re not careful. To avoid these problems:

- Understanding Pricing Structures: Ensure you have a clear understanding of the pricing model and any potential additional costs.

- Importance of Detailed Quotes: Request detailed quotes that outline all costs associated with your project.

- Negotiation Tips: Don’t hesitate to negotiate terms to ensure transparency and fairness.

By being proactive, you can mitigate the risk of unexpected expenses and quality concerns.

Why Rushing the Printer Selection Process Can Be Risky

Rushing the printer selection process can lead to poor decisions. Consider the following:

- Consequences of Rushed Decisions: Hasty choices may result in selecting a printer that doesn’t meet your needs.

- Importance of Thorough Research: Take the time to research potential partners and evaluate their capabilities.

- Long-term Impacts: A poor choice can have lasting effects on your brand’s image and marketing efforts.

By allowing adequate time for the selection process, you can make a more informed decision.

| Factor | Description | Importance |

|---|---|---|

| Quality of Printing | Assess the quality of samples and previous work | High |

| Capabilities | Understand the range of services offered | High |

| Reputation | Research customer feedback and reviews | High |

| Printing Technology | Description | Best Use |

|---|---|---|

| Digital Printing | Ideal for short runs and quick turnaround | Marketing materials, short-run projects |

| Offset Printing | Best for high-volume projects with consistent quality | Brochures, catalogs, large volume print jobs |

| Large Format Printing | Suitable for banners and signage | Trade shows, events, outdoor advertising |

Choosing the right commercial printing partner is a critical decision that can significantly impact your business. By understanding the essential factors, assessing potential providers effectively, and avoiding common mistakes, you can ensure a successful partnership that meets your printing needs.